Encoders Incremental

Sendix 5020

|

|

The Standard Encoder for automation.

Sendix 5000 / 5020 incremental encoders offer special resistance to vibrations and installation error due to their robust bearing construction using the Safety Lock™ design. The stable die-cast housing, the high protection up to IP67 and the wide temperature range from -40 °C to +85 °C allow universal use. This family of encoders is subject to continuous technical development and now offers a unique variety of ordering options.

| Mechanical | |

|---|---|

| Dimension | Ø 50 mm |

| Shaft type |

6 mm hollow shaft, through 8 mm hollow shaft, through 10 mm hollow shaft, through 12 mm hollow shaft, through 14 mm hollow shaft, through 15 mm hollow shaft, through 1/4 " hollow shaft, through 3/8 " hollow shaft, through 1/2 " hollow shaft, through 5/8 " hollow shaft, through |

| Flange type |

Spring element, long Stator coupling Torque brackets long Ø 50.80 mm Ø 57.20 mm Ø 63.00 mm Ø 65.00 mm |

| Working temperature | -40 °C ... +85 °C |

| Protection level |

IP65 IP66 IP67 |

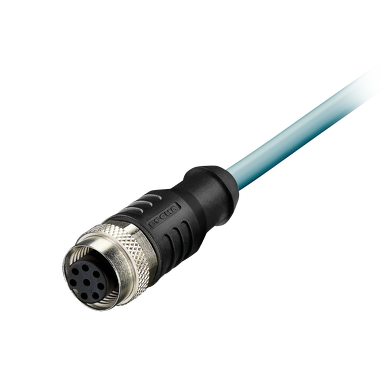

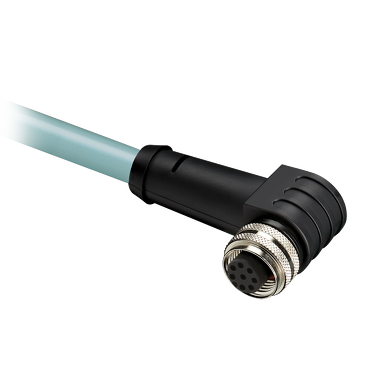

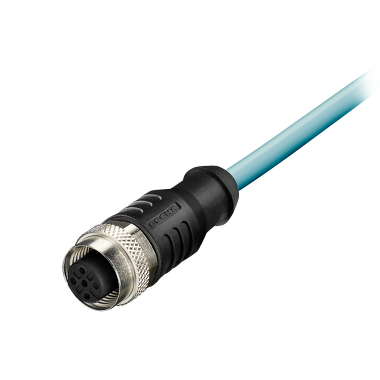

| Connection types |

Axial cable Radial cable Tangential cable M23 connector radial M12 connector radial MIL connector |

| Max. rotational speed |

12.000 min-1 |

| Weight | 400 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. |

5.000 ppr incremental |

| Power supply |

5 V DC 5...30 V DC 10...30 V DC |

| Interfaces |

Gegentakt TTL / RS422 Open Collector |

| Options | |

|---|---|

| on request |

|

- Increased resistance against vibrations and tolerance of installation errors, elimination of machine downtime and repairs thanks to sturdy bearing construction in “Safety-LockTM Design”.

- Ensures highest safety against field breakdowns and is thus suitable also for outside use thanks to its resistant die-cast housing and protection up to IP67.

- Undetachable clamping ring on hollow shaft encoders.

- Wide temperature range, -40°C ... +85°C.

- Suitable connection variant for every specific case:

- cable connection with different standard lengths, M12 (5- or 8-pin), M23 (12-pin), MIL (7- or 10-pin) and Sub-D connector.In addition: Variants with connector fitted in the cable – for error-free electrical connection to your control.

- Reliable mounting in a wide variety of installation situations: comprehensive and proven fixing possibilities.

- Compatible with all US and European standards.

- Wide range of standard pulse ranges up to max. 5000 pulses per revolution.

Accessories

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.1602.0000 |

Isolation insert, hollow shaft Ø 15mm

Thermal and electrical isolation of the encoders (Temperature range -40 ... +115°C). Isolation inserts prevent currents from passing through the encoder bearings. These currents can occur when using inverter controlled threephase or AC vector motors and considerably shorten the service life of the encoder bearings. In addition the encoder is thermally isolated as the plastic does not transfer the heat to the encoder.Isolation insert (plastic).

| Innendurchmesser 8 mm | 8.0010.4020.0000 |

| Innendurchmesser 6 mm | 8.0010.4021.0000 |

| Innendurchmesser 1/4" | 8.0010.4022.0000 |

| Innendurchmesser 10 mm | 8.0010.4023.0000 |

| Innendurchmesser 3/8" | 8.0010.4024.0000 |

| Innendurchmesser 12 mm | 8.0010.4025.0000 |

| Innendurchmesser 1/2" | 8.0010.4026.0000 |

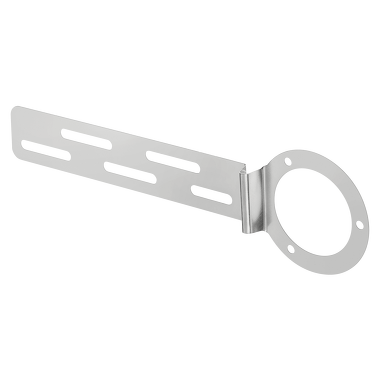

Torque stop, flexible

For hollow shaft encoderswith flange ø 58 mm

Mounting radius 39.5 ... 142.75 mm

Designed for functional safety technology.

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 M3x6 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.4047.00FS |

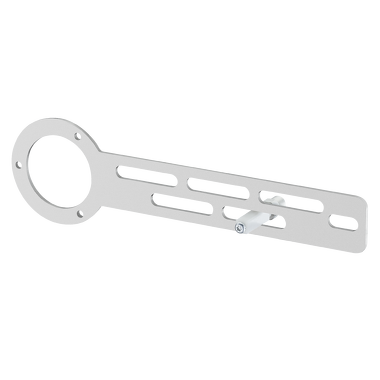

Fastening arm set, rigid

For hollow shaft encoderswith flange ø 58 mm

Mounting radius 32.5 ... 143.5 mm

Designed for functional safety technology.

For applications with very low axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 M3x6 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 torque pin 8.0010.4049.0075

| 8.0010.4051.00FS |

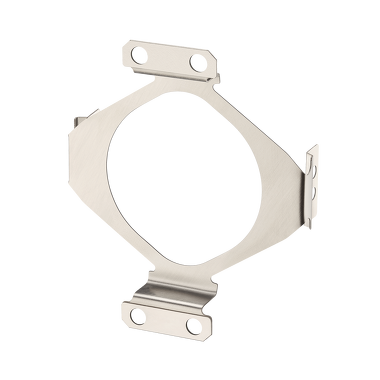

Stator coupling (FS)

For hollow shaft encoders

with flange ø 58 mm

Mounting radius 31.5 mm

Designed for functional safety technology by 4-screw principle.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws M3x6 for mounting to the encoder

Connection to application (not included in delivery)

- 4 screws

| 8.0010.40B2.00FS |

Fastening arm, medium (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.5 ... 45.75 mm

For applications with axial and radial play with constant rotary movements.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40E0.0000 |

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.40L0.0000 |

Fastening arm, short (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.25 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40M0.0000 |

Spring tether element

For hollow shaft encoderswith flange ø 50 ... 58 mm

For applications with low radial and axial play and low dynamics.

Scope of delivery

- Wire spring element

- 1 screw for fastening to the encoder.

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40W0.0000 |

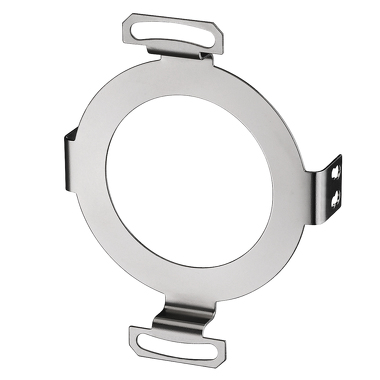

Stator coupling, double-winged

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 31.5 mm

For lateral mounting on the encoder flange. For applications with high accuracy requirements.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 2 screws

| 8.0010.4D00.0000 |

Spring element, short

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 16 ... 27 mm

For applications with limited axial clearance at low dynamics and limited installation space.

Scope of delivery

- Spring element (plastic)

- 1 screw for fastening to the encoder

Connection to application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4H00.0000 |

Spring element, long

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 30.7 ... 36.7 mm

For applications with high axial backlash, at low dynamics.

Scope of delivery

- Spring element (plastic)

- 1 screw for fastening to the encoder

Connection to application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4I00.0000 |

Fastening arm, long, (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 36.5 ... 85 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.4R00.0000 |

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.