Encoders Absolute singleturn

Sendix 5858

|

|

For real-time communication: Industrial Ethernet encoders with EtherCAT interface.

The singleturn encoders 5858 and 5878 with second-generation EtherCAT interface and optical sensor technology are ideal for use in all applications with an EtherCAT interface. The data communication is based on CAN over EtherNet and ideally suited for use in real time applications. These encoders are available with a solid shaft up to a maximum of 10 mm or a blind hollow shaft up to 15 mm.

Connectivity stands for the ability to communicate additional information and / or to be integrated in a network. This can take the form of additional interfaces such as OPC-UA (e.g. for additional edge communication) or Industrial Ethernet communication as well as a digital interface such as "BISS" or "SCS open link".

Identification is the ability to transmit technical information by means of an electronic data sheet / type plate. In addition, further information about the machine can be transmitted (e.g. information about the axis where the encoder is installed). Essentially, all the information required in the application for asset management is recorded here.

| Mechanical | |

|---|---|

| Dimension | Ø 58 mm |

| Shaft type |

6 mm shaft, with flat surface 10 mm shaft, with flat surface 1/4 " shaft, with flat surface 3/8 " shaft, with flat surface |

| Flange type |

Synchro flange / Servo flange Clamping flange Square flange Ø 58.00 mm ❏ 63,50 mm |

| Working temperature | -40 °C ... +80 °C |

| Protection level |

IP65 IP67 |

| Connection types |

M12 connector radial |

| Max. rotational speed |

9.000 min-1 |

| Weight | 500 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. |

16 bits singleturn |

| Power supply |

10...30 V DC |

| Interfaces |

EtherCAT |

- EtherCAT conformance tested.

- Integration of the latest slave – EtherCAT stack from Beckhoff, version 5.01.

- Ideally suited for use in harsh outdoor environments, thanks to IP67 protection and rugged housing construction.

- Use of CoE (CAN over EtherNet).

- Genuine new position information as a result of minimal cycle time of 62.5 μs in the DC mode.

- Faster, easier error-free connection thanks to M12 connectors.

- Supports Hot-Connect.

Accessories

Bellows coupling

Bellows couplings provide cost-effective connection of the motor and encoder. They are also able to correct any angular errors between the drive and encoder. Compensating larger angle displacements.Bellows coupling (stainless steel).

| 8.0000.1102.0606 |

Assembly bell

For shaft encoders with flange ø 50 ... 58 mmFast encoder mounting. Electrical and thermal insulation through glass-fibre reinforced plastic and insulating spring washer coupling - complete delivery as a set.

Scope of delivery

- Mounting bell

- Spring washer coupling (8.0000.1401.XXXX)

- Mounting eccentric (8.0000.4B00.0000)

- Mounting accessories

| 8.0000.4500.XXYY |

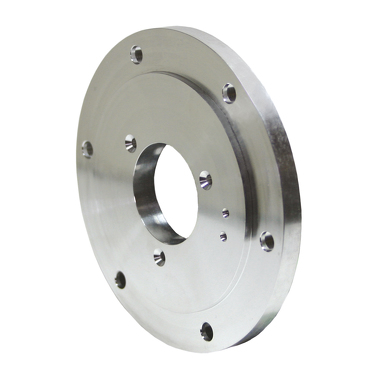

Adapter flange, square, 4 mm

For shaft encoders with clamping flange ø 50 ... 58 mmScope of delivery

- Flange adapter (aluminum)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 4 screws

| 58,0 mm x 4 mm | 8.0010.2100.0000 |

| 63,5 mm x 3 mm | 8.0010.2120.0000 |

| 70,0 mm x 10 mm | 8.0010.2600.0000 |

| 80,0 mm x 4 mm | 8.0010.2800.0000 |

Flange, Ø 115mm Euroflange

For shaft encoders with flange ø 50 ... 58 mmScope of delivery

- Flange adapter (aluminum)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 6 screws

| Drehgeber 580x/5000 | 8.0010.2160.0000 |

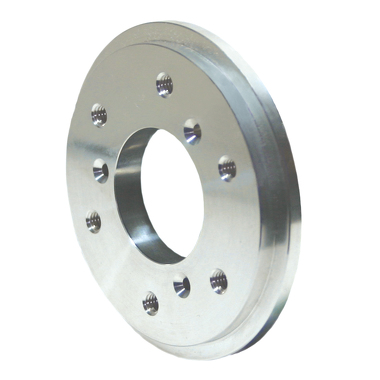

Flange, Ø 58mm

For shaft encoders with flange ø 50 ... 58 mm.Adapter for converting a clamping flange into a synchro flange.

Scope of delivery

- Flange adapter (aluminum)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 3 screws

| 8.0010.2180.0000 |

Flange, Ø 65mm

For shaft encoders with flange ø 50 ... 58 mmWith this flange adapter, Kübler encoders of size 58 mm can replace third-party encoders of size 65 mm.

Scope of delivery

- Flange adapter (aluminum)

- 3 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.2230.0000 |

Flange, Ø 90mm

For shaft encoders with flange ø 50 ... 58 mm.Adapter for converting a clamping flange into a synchro flange. Mechanically compatible with encoder type 9000.

Scope of delivery

- Flange adapter (aluminum)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 6 screws

| 8.0010.2270.0000 |

Angular flange

For shaft encoders with flange ø 50 ... 58 mmScope of delivery

- Angle flange (aluminium)

- 3 screws for fastening to the encoder.

Connection to the application (not included in delivery)

- 2 screws

| 8.0010.2300.0000 |

Bearing box

For shaft encoder with clamping flange ø 58 mm and shaft 10 x 20 mmWhen the encoder is driven by a toothed or chain wheel, V-belt or toothed belt, impeller, etc., the permissible axial or radial shaft loads are usually exceeded during operation. For these cases, the bearing box equipped with reinforced bearings is ideally suited.

Scope of delivery

- Bearing box with lock and O-ring

- Coupling for shaft 10 mm

- Adapter flange 8.0010.2100.0000

- Mounting accessories

| 8.0010.8200.0004 |

Robust bearing unit

For shaft encoders with clamping flange ø 50 ... 58 mm and shaft 10 mmThe separation of the bearing load and the sensor system provides the encoder with additional protection in harsh environments.

Scope of delivery

- Robust bearing unit

- 3 x cheese head screw M4x25 (SW3)

- 1 x O-ring

| 8.0010.8200.000C |

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.