Encoders Incremental

Sendix KIH50

|

|

The economical sensor solution.

The encoders Sendix Base KIS50 / KIH50 offer a protection level up to IP65 and can be used with temperatures from -20°C up to +70°C. They are ideal for use in standard applications and in simple machines.

The Sendix Base KIS50 / KIH50 family also features our well proven safety lock system, allowing higher tolerance of possible installation errors and increasing the overall performance of this encoder.

| Mechanical | |

|---|---|

| Dimension | Ø 50 mm |

| Shaft type |

8 mm hollow shaft, through 10 mm hollow shaft, through 12 mm hollow shaft, through 14 mm hollow shaft, through 15 mm hollow shaft, through |

| Flange type |

Ø 50.80 mm Ø 63.00 mm Ø 65.00 mm |

| Working temperature | -20 °C ... +70 °C |

| Protection level |

IP65 |

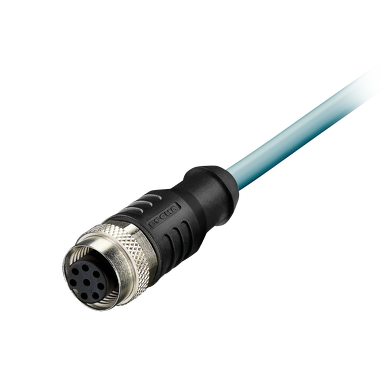

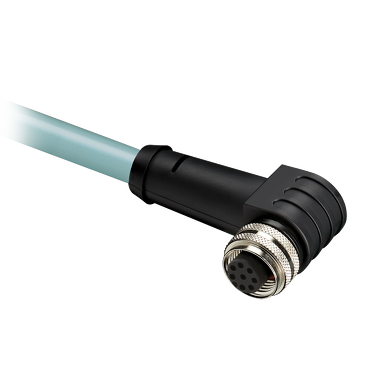

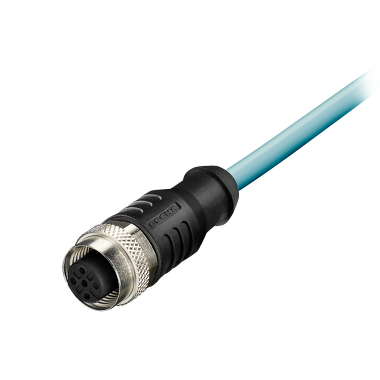

| Connection types |

Radial cable Tangential cable M23 connector radial M12 connector radial |

| Max. rotational speed |

6.000 min-1 |

| Weight | 170 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. |

5.000 ppr incremental |

| Power supply |

5 V DC 5...30 V DC 10...30 V DC |

| Interfaces |

Gegentakt TTL / RS422 Open Collector |

- Resistant die-cast housing and protection up to IP65.

- Wide temperature range, -20°C ... +70°C.

- Elimination of machine downtime thanks to sturdy bearing construction in “Safety-LockTM Design”.

- Suitable connection variant for every specific case: cable connection, M12 and M23 connector.

- Various mounting options.

- Up to 5000 pulses per revolution.

Accessories

Bellows coupling

Bellows couplings provide cost-effective connection of the motor and encoder. They are also able to correct any angular errors between the drive and encoder. Compensating larger angle displacements.Bellows coupling (stainless steel).

| 8.0000.1102.0606 |

Fastening arm, medium (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.5 ... 45.75 mm

For applications with axial and radial play with constant rotary movements.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40E0.0000 |

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.40L0.0000 |

Fastening arm, short (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.25 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40M0.0000 |

Spring tether element

For hollow shaft encoderswith flange ø 50 ... 58 mm

For applications with low radial and axial play and low dynamics.

Scope of delivery

- Wire spring element

- 1 screw for fastening to the encoder.

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40W0.0000 |

Spring element, short

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 16 ... 27 mm

For applications with limited axial clearance at low dynamics and limited installation space.

Scope of delivery

- Spring element (plastic)

- 1 screw for fastening to the encoder

Connection to application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4H00.0000 |

Spring element, long

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 30.7 ... 36.7 mm

For applications with high axial backlash, at low dynamics.

Scope of delivery

- Spring element (plastic)

- 1 screw for fastening to the encoder

Connection to application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4I00.0000 |

Fastening arm, long, (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 36.5 ... 85 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.4R00.0000 |

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.