Measuring wheel systems

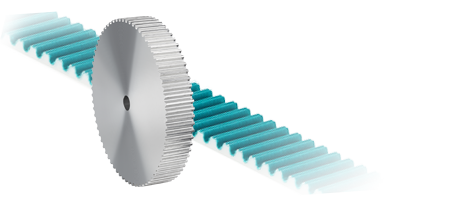

Slip-free detection of linear movements

- Spring arms and spring brackets, contact forces up to 40 N

- Operating travel 10 mm to 80 mm

- Different measuring wheel surfaces

- Incremental and absolute encoders

Systems for speed measurement, position detection and length measurement

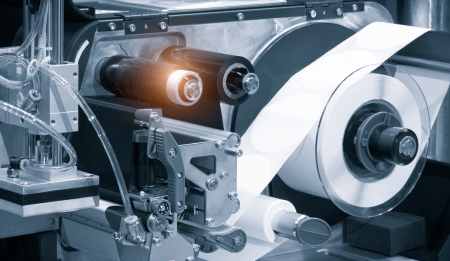

Measuring wheel systems from Kübler are the ideal solution for reliable speed measurement, position detection and length measurement in applications with linear movements. These are recorded rotationally via the measuring wheel with attached encoder directly on the surface of the material to be measured and converted into linear data. Integrated springs ensure the necessary contact force of the measuring wheel on the measuring surface for reliable measured value acquisition.

To the brochureMeasuring wheel systems are used for the detection of linear movements

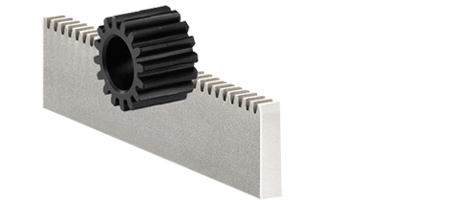

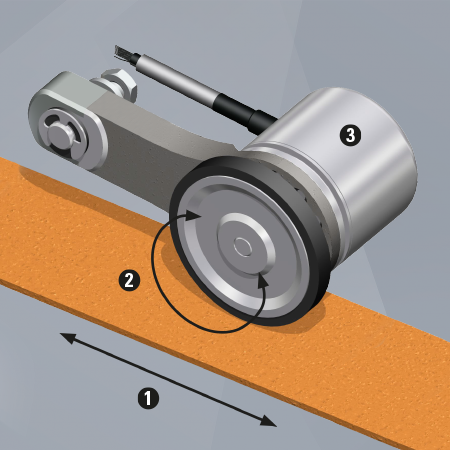

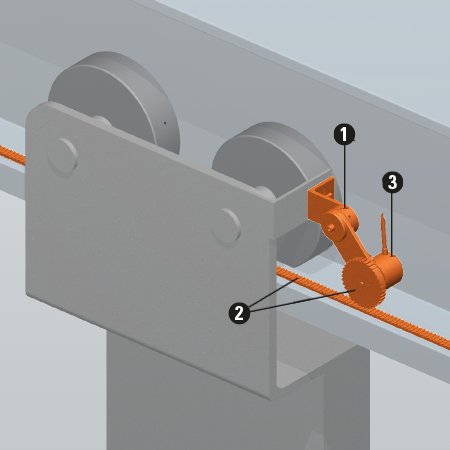

The linear movement (1) of a material to be measured is converted into a rotational movement (2) by a contacting measuring wheel (or pulley or pinion).

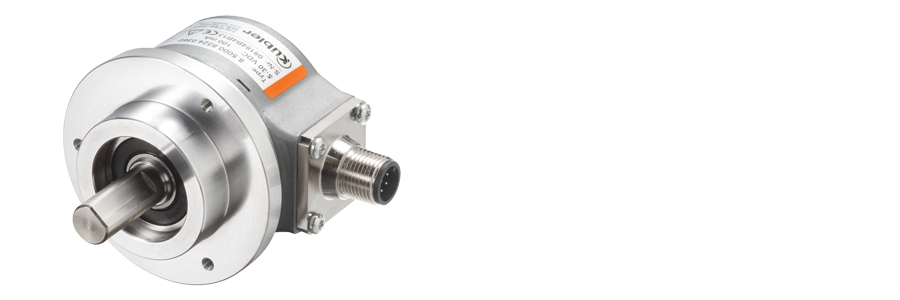

An attached incremental or absolute encoder (3) detects this rotation and converts it into speed, position and distance values.

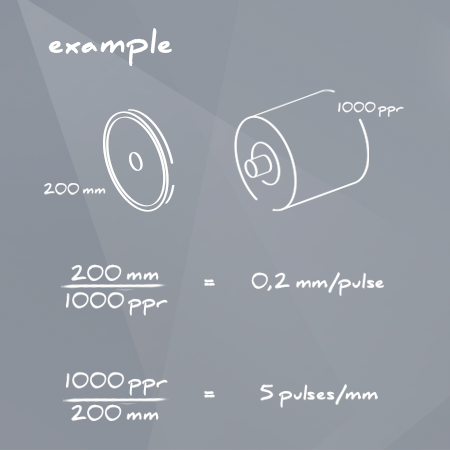

The linear resolution of the measuring wheel system (mm) results from the ratio of the measuring wheel circumference and the rotary resolution of the encoder (ppr).

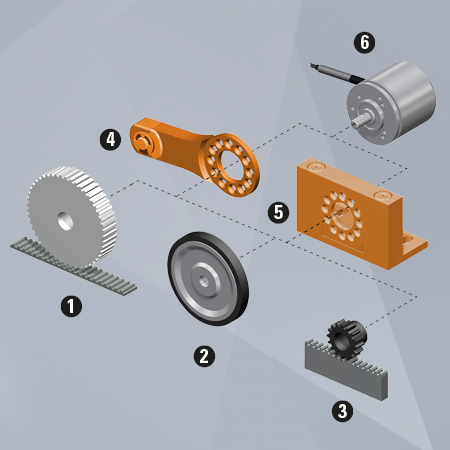

3-part structure of the measuring wheel systems – System components

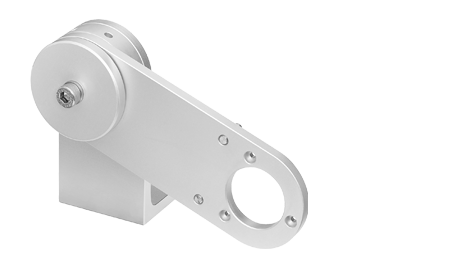

Detection of the linear movement

by a measuring wheel (2), a pulley with toothed belt (1) or a pulley with toothed belt (3), which travels along with a material to be measured.

Data detection / data transfer

by a Kübler Sendix encoder (6), which is connected to the measuring wheel.

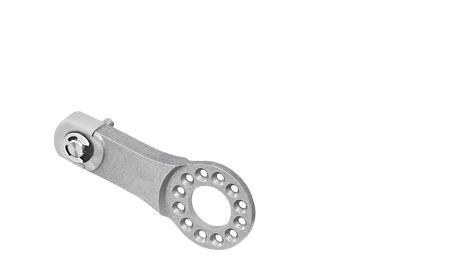

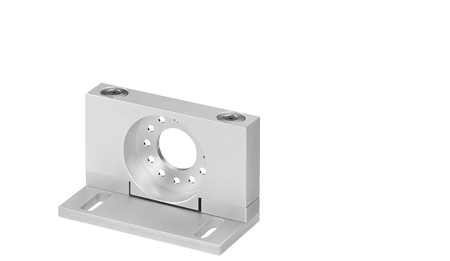

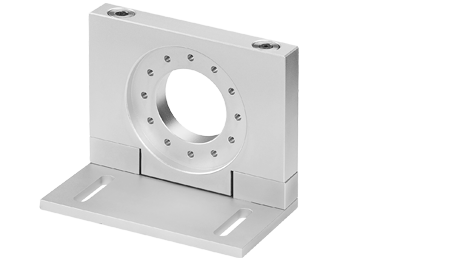

Spring-loaded encoder holder

Spring arms (4) and spring brackets (5) in different sizes and with different contact forces.

Integrated springs ensure slip-free measurement.

Calculation of the measuring steps

The linear resolution of the measuring wheel system (mm) results from the ratio of the measuring wheel circumference and the rotary resolution of the encoder (ppr).

- Distance per pulse = measuring wheel circumference / number of pulses encoder = mm / ppr

- Pulse per distance = number of pulses encoder / measuring wheel circumference = ppr / mm

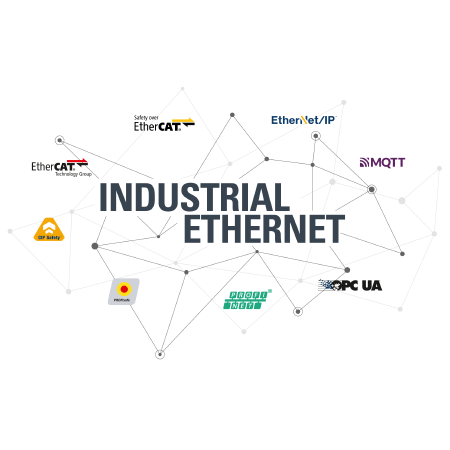

„IIoT / Industry 4.0 ready“

This means that, in addition to the classic measuring task and transmission of measured values, rotary encoders must also offer further functionalities for networking products and collecting or transmitting additional information.

Which Industrie 4.0 functionalities an encoder needs to be "Industrie 4.0 ready" depends on the overall concept. The decisive factor here is the role assigned to the encoder. Either as an independent Industrie 4.0 object (asset) or as part of it. This determines whether the encoder must have its own management shell or is integrated into an existing management shell.

Learn more

The use of Industrial Ethernet communication in modern industry is continuously increasing. In the future, in line with the Industrie 4.0 idea, all areas of industrial production plants will be united in a single network on the Industrial Ethernet platform, from the field devices to the control level to the cloud. And this with real-time data exchange.

The corresponding communication capability of the sensors plays an essential role here.

Measuring wheel systems – individually configurable

Pre-assembled systems consisting of spring arm or spring bracket with matching measuring wheel and encoder

System components – spring arms and spring brackets

Freely combinable with matching encoders and measuring wheels

System components - Encoders

Incremental or absolute – the right sensor technology for every application

Evaluation

Extension of the functionality of the measuring wheel systems with Kübler products for evaluation and control

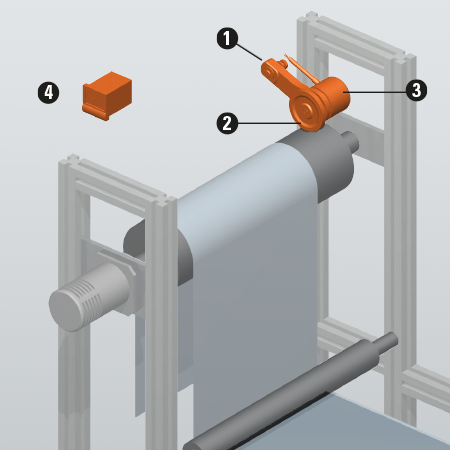

Speed measurement on a guide shaft

Requirement

• Reliable speed measurement

• Continuous contact force

• Easy to integrate

• Compact design

Kübler Solution – Measuring wheel system MWE21

(1) Spring arm: MWE20

(2) Measuring wheel: circumference 200 mm, plastic smooth

(3) Encoder: Sendix KIS40, 1000 ppr

(4) Preset counter: Codix 924 – visualization and control of speeds

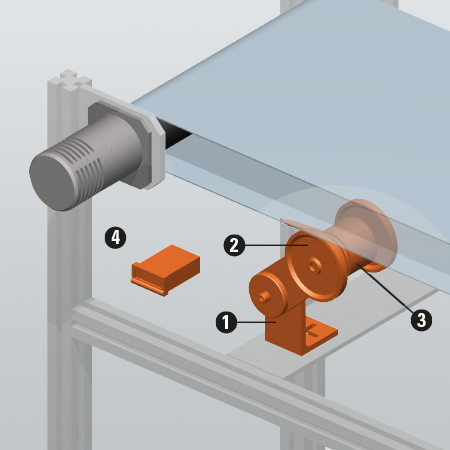

Speed measurement on a conveyor belt

Requirement

• Direct measurement on the measured material (Not via motor encoder → Slippage in the system)

• Can be mounted from below against the conveyor belt (Overhead mounting)

• High contact force

• Large spring travel (Tolerance compensation from conveyor belt)

• Redundant double measuring wheel system (two support points for the measuring wheels)

Kübler Solution – Double measuring wheel system MWE62

(1) Spring arm: MWE60

(2) Measuring wheel: circumference 300 mm, Double O-ring

(3) Encoder: Sendix KIS50, 1000 ppr

(4) Preset counter Codix 571T – color change of the display when reaching or falling below measured values

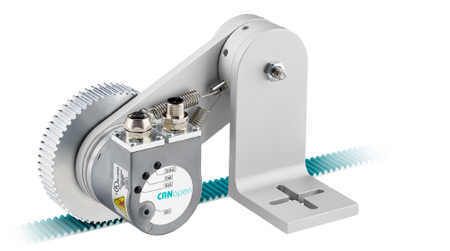

Position measurement on gantry crane

Requirements

• 100 % slip-free measurement

• Exact positioning

• Absolute position feedback

• High contact force

• High shock resistance

Kübler Solution – Measuring wheel system MWE61

(1) Spring arm: MWE60

(2) Measuring wheel: Pulley with toothed belt

(3) Encoder: Sendix F5868 PROFINET

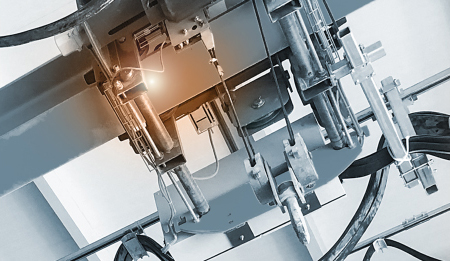

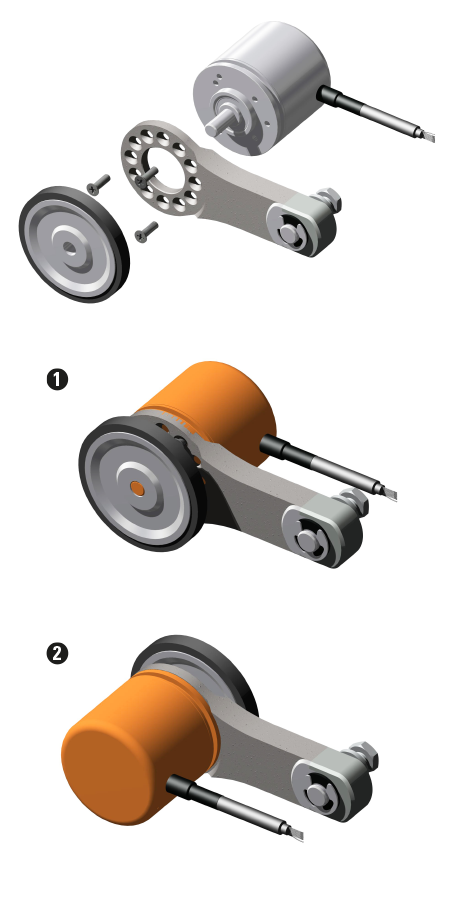

Mounting encoder on spring arm or spring bracket

The encoder is attached to the spring arm or spring bracket with 3 screws.

With the MWE20 spring arm, the encoder can be mounted on both sides:

(1) Mounting left (factory setting)

(2) Mounting right

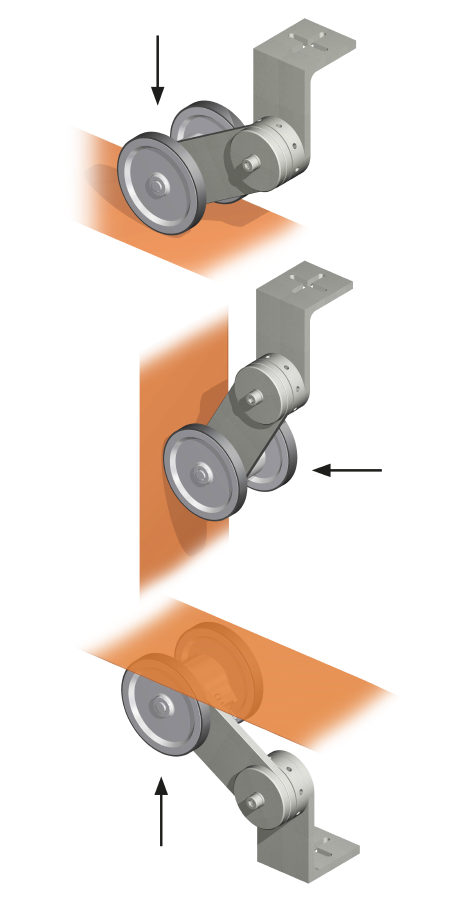

Wide range of installation options

The measuring wheel systems with spring arm can be mounted on the application in a variety of ways.

(1) downwards

(2) to the side

(3) upwards (over head)

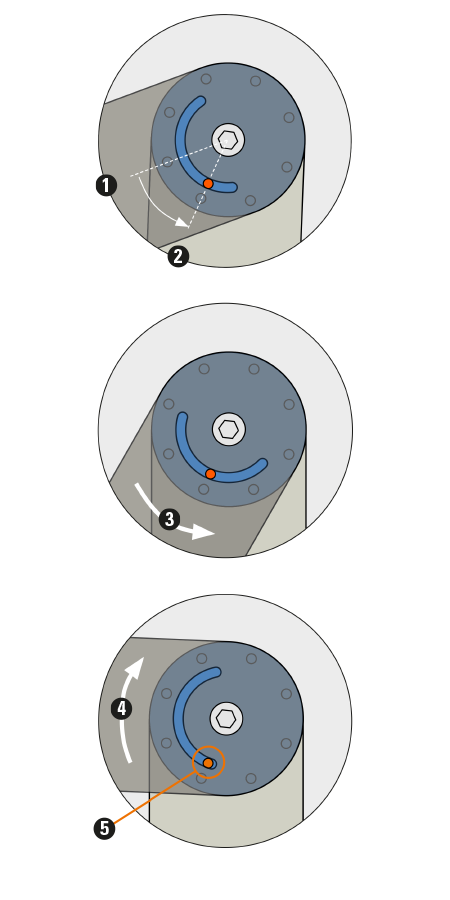

Adjusting the preload and spring travel limitation on the MWE60 spring arm

Starting from the mounting on the application (1), the desired preload (2) for the contact force is selected via an adjustment wheel.

Starting from the preload, the spring arm can rotate in the direction of the spring force (3).

Against the spring force (4), the spring arm rotates up to a stop (5) corresponding to approx. 40 N.

This spring travel limitation prevents overloading of the spring.

Technology in detail – measuring wheels

Different measuring wheel coatings for different surfaces of the material to be measured

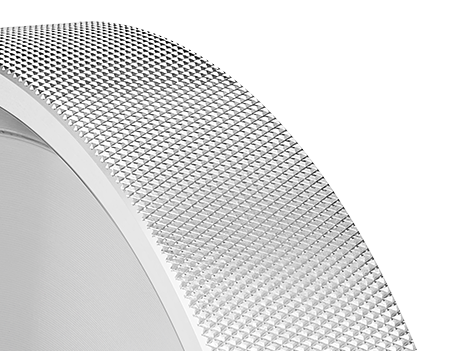

Measuring wheel with diamond knurled coating

- Measuring wheel coating made of aluminum with cross knurl running surface

- Suitable for cardboard, wood , textiles, rubber or soft plastic

- Available with circumference 100 / 200 / 300 / 500 mm and 6" / 12"

To the measuring wheels

Measuring wheel with smooth plastic coating

- Measuring wheels made of aluminum with smooth plastic coating (polyurethane)

- Suitable for cardboard, paper, wood, textiles, plastic, painted surfaces, wire, greased metals, steel profiles, leather

- Available circumference: 100 / 200 / 300 / 500 mm and 6" / 12"

To the measuring wheels

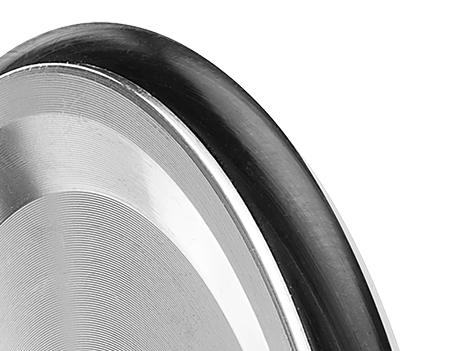

Measuring wheels with O-ring or double O-ring

- Measuring wheel coating made of aluminum with single or double O-ring

- Suitable for cardboard, paper, wood, textiles, plastic, painted surfaces

- Available with circumference 200 / 300 mm and 6" / 12"

To the measuring wheels

Measuring wheel with tufted rubber

- Measuring wheel coating made of aluminum with tufted rubber (polyurethane)

- Suitable for cardboard, paper, wood, textiles, plastic,carpet, cable, fleece

- Available with circumference 200 / 300 / 500 mm and 12"

To the measuring wheels

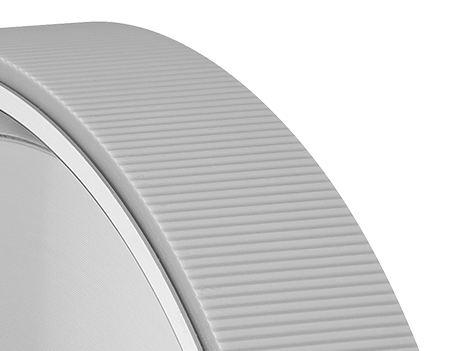

Measuring wheel with corrugated plastic coating

- Measuring wheel coating made of corrugated plastic (polyurethane)

- Suitable for cardboard, paper, wood, textiles, plastic, metals ungreased, glass, flooring, painted surfaces.

- Available with circumference 200 / 300 / 500 mm and 12"

To the measuring wheels

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.