Industry 4.0 / IIoT

Encoders and Slip Rings for Industrial Internet of Things (IIoT)

The implementation of IIoT concepts in practice is one of the central challenges for every development engineer. The definition of individual concepts is the first step. In concrete terms, this means: which of the possibilities offered by IIoT should be used?In addition to a wide range of "Industry 4.0 / IIoT ready" encoders and slip rings, Kübler also offers support during implementation.

Industry 4.0 / IIoT ready

Networked and intelligent products are a prerequisite for IIoT. They are able to say:"Who am I? Where am I? How do I feel?"

"Industry 4.0 / IIoT ready" means: In addition to the classical measuring task and transmission of measured values of an encoder, in addition to the transmission of power, signals and data of a slip ring, the Industry 4.0 / IIoT ready products must also provide further functionalities for networking the products and for collecting or transmitting additional information.

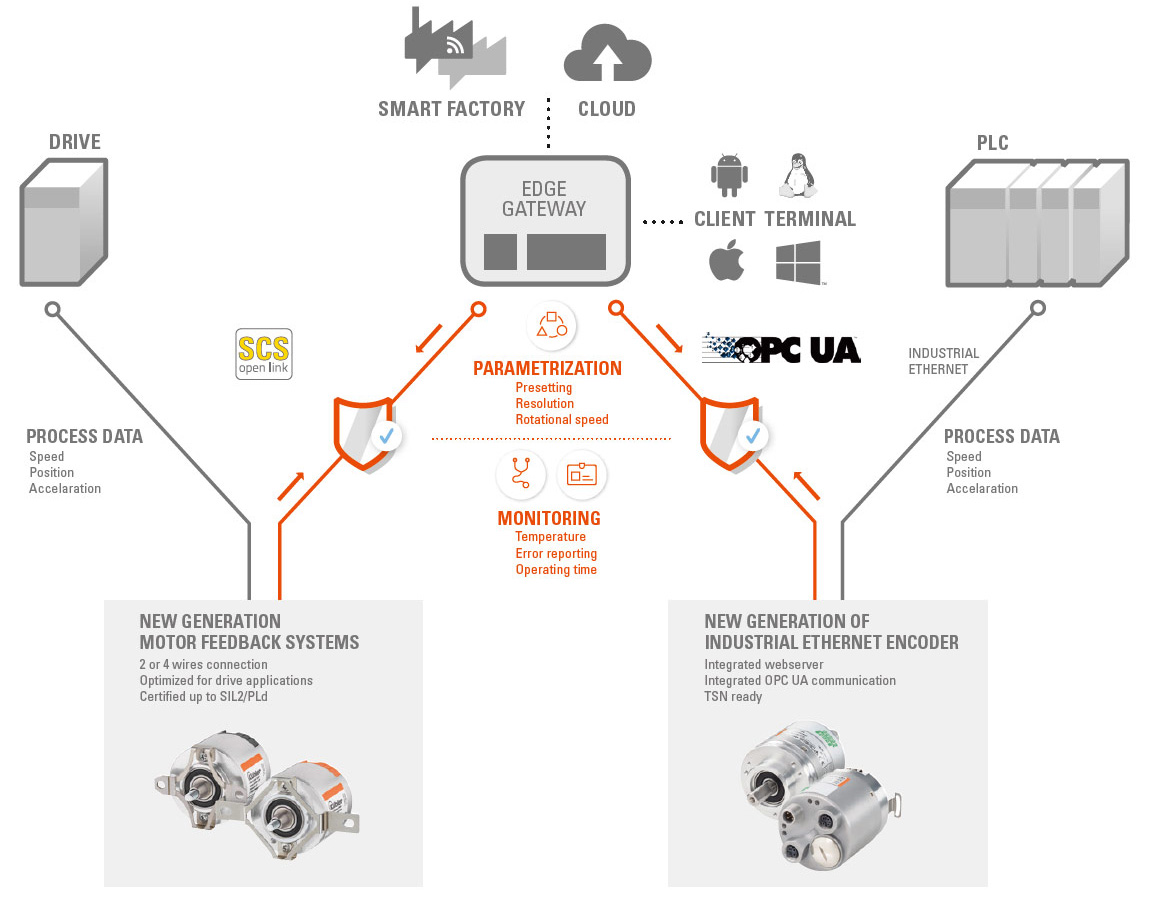

Connectivity

Connectivity stands for the ability to communicate additional

information and / or to be integrated in a network. This can take the

form of additional interfaces such as OPC-UA (e.g. for additional

edge communication) or Industrial Ethernet communication as well

as a digital interface such as "BISS" or "SCS open link".

Identification

Identification is the ability to transmit technical information by

means of an electronic data sheet / type plate. In addition, further

information about the machine can be transmitted (e.g. information

about the axis where the encoder is installed). Essentially, all the

information required in the application for asset management is recorded here.

Diagnostics

Diagnostics functions provide relevant information about the condition of the product (e.g. error messages) or indirect information about the application.

For example, an integrated temperature sensor can indicate that the permissible working temperature range has been exceeded. Or integrated vibration sensors provide information on the condition of the power train bearings.

Highly integrated bearingless systems in particular can provide reliable information here. Log and time stamp functions in Industrial Ethernet encoders make it possible to create lifetime histograms.

Adaptability

Adaptability refers to adaptability, which can take place on two

levels:

- At the operational level, the parameters / settings of an encoder can be changed during operation, e.g. to optimize setup processes or to eliminate measurement errors with digital signal processing.

- Software updates can be carried out at system level at any time.

concepts can be subsequently extended in order to guarantee the

future viability of the system. Therefore, all Kübler fieldbus and

Industrial Ethernet encoders are available with a firmware update

function as standard.

Encoders - Industry 4.0 / IIoT ready

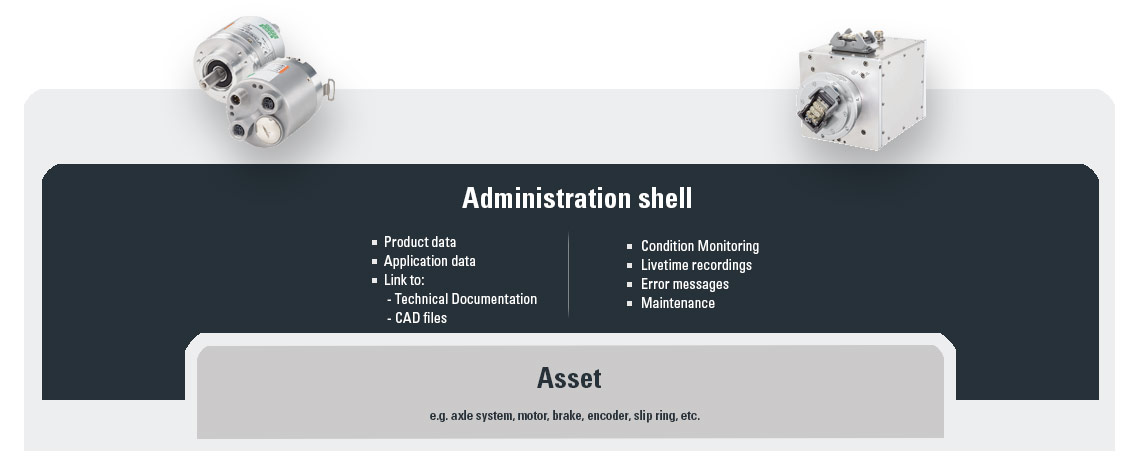

Which Industry 4.0 / IIoT functionalities an encoder needs to be "Industry 4.0 / IIoT ready" depends on the overall concept. The decisive factor here is the role assigned to the encoder. Either as a part of or as an independent Industry 4.0 / IIoT object (asset). This determines whether the encoder must have its own administration shell or be integrated into an existing administration shell.

An encoder with its own administration shell not only has functions on the "field level", but also on the "control level" or up to direct "edge communication". In the highest configuration level, for example, we speak of an Industrial Ethernet encoder with integrated web server and additional OPC-UA protocol.

In most cases, however, the encoder is integrated within an asset, such as a power train. The Industry 4.0 / IIoT object is then a drive axis consisting of motor, gear unit, encoder, brake, inverter, etc. In this case, the question arises as to which of the elements in the object should be the administration shell and also takes over the administrative functions. The encoder can fulfill this role (completely or partially), as the electronic data sheet contains not only the information about the encoder itself but also about the entire power train. These are e.g. motor data, location information, etc.. In principle, the administration shell represents the virtual representation of the product (digital twin) and the technical functions. This makes a large number of use cases possible, from simulation to asset management.

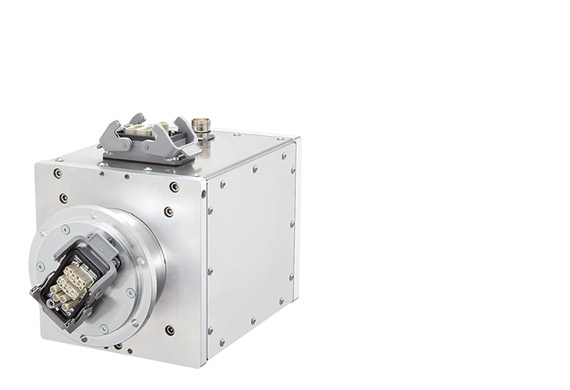

Slip rings - Industry 4.0 / IIoT enabler

Slip rings for the transmission of Industrial Ethernet ensure that Industry 4.0 / IIoT concepts can be implemented in every angle of the machine. For applications where maximum availability is required, Kübler also offers contactless solutions. Slip rings are highly integrated components of complex machines. This enables them to provide a particularly large amount of reliable information about the machine condition and maintenance requirements. Kübler therefore uses the slip rings as "Industry 4.0 / IIoT enabler" and has integrated sensor systems into its smart slip rings without taking up additional valuable installation space. The precise measurement and monitoring of axis movements, vibrations and temperature coupled with the storage of lifetime histograms provides all the necessary information for condition monitoring. Asset management functions are supported by machine-specific electronic data sheets. Both are important for the implementation of efficient predictive maintenance and also enable

new services such as "Product-as-a-Service (PaaS)". As a result, the slip ring is transformed from a passive transmission element into an active component of Industry 4.0 / IIoT.

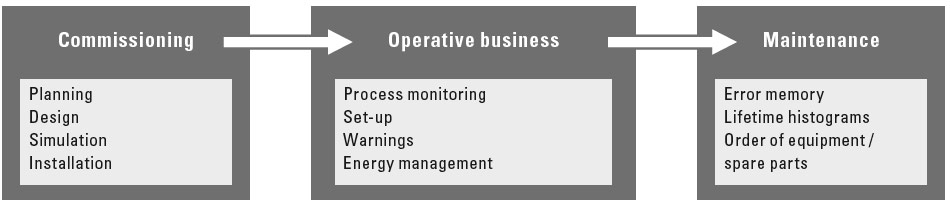

Use-Cases

Industrial Internet of Things opens up new perspectives and new business ideas. Compared to the current automation world, which is mainly device-oriented, Industry 4.0 / IIoT offers a complete system view. In addition, the technology enables manufacturer-independent access to device data, additional standardized services and simplified device administration. The implementation should take place step by step and be based on practical applications or implementations (use cases). Therefore, we recommend defining the individual use cases first and then planning the technical implementation.

From the point of view of the device manufacturer, the service partner (installation, commissioning and maintenance) and the operator (factory owner).

Although predictive maintenance is very often mentioned in connection with the practical implementation of Industry 4.0 / IIoT, it is only one of many use cases. Especially the definition of use cases shows the versatile advantages of Industry 4.0 / IIoT.

Asset management

This is about the system description with technical data sheet, functional description and location information but also about the direct reference to the information available in a cloud such as CAD data and life cycle information. In short, everything you need to make a digital twin.Interoperability

Contains all processes from system-independent and cross-system communication to cloud communication. Thus, both individual devices and the cloud (device cloud and system cloud) become an integral part of the communication between OT (Operation Technology) and IT (Information Technology).Diagnostics / Data Trace

By measuring, monitoring and visualizing critical processes, data is collected, evaluated and made available for big data. This data serves as a basis for predictive maintenance or energy management, but also for simulations or more effective installation of equipment, machines and plants.

Commissioning a power train with Industrial Ethernet encoders

Effective, fast and error-free installation and commissioning can be easily implemented within the framework of Industry 4.0 / IIoT.

The electronic type plate of the motor and encoder, stored in the "Administration shell" of the encoder, as well as information on the operating range, maximum speed, maximum temperature and the installation location, provide the user with all the important information about the installation.

The links to operating instructions, manuals and CAD data are also stored directly in the encoder and can therefore be easily retrieved from the Kübler server. The latest software versions or application-specific parameterization can be downloaded directly from the device cloud via the additional OPC-UA interface without having to go through the controller.

This data can be transferred to an asset management system that supports production planning. Corresponding simulations can also be run in advance to rule out possible planning errors. During commissioning, the encoder itself can e.g. support the oscilloscope function described in the ZVEI 4.0 drive concept, e.g. for fast and simple definition of specific trigger conditions. Error memories and extensive warnings and status messages support troubleshooting.

Slip rings as a Product-as-a-Service (PaaS)

For almost every machine it is important to reduce downtimes to a minimum. These are very often influenced by the maintenance cycles of installed slip rings. Since slip rings are highly integrated components of the machine, maintenance or repairs are correspondingly critical.

Kübler has the solution: thanks to the integrated sensor system in the slip ring, condition monitoring functions can be implemented. Operating states such as number of revolutions, maximum and average speeds, temperatures, service life, shock and vibrations are recorded and stored.

This leads to extensive monitoring of the axis. The captured data is then transferred directly to the cloud and serves as the basis for predictive maintenance. The evaluated data can be used, e.g., to plan and implement scheduled maintenance of the slip ring managed by the Kübler service team. This ensures maximum availability of the entire system. The customer not only buys the product, but also secures a permanent and reliable transmission in the sense of "PaaS" through the services offered by Kübler (from installation and commissioning to maintenance or repair).

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.