Functional safety for wind turbines

High system availability and safety

- Certified encoders up to SIL3/PLe

- Incremental and absolute rotary encoders

- Bearingless encoders

- Safe speed monitors

- Competent advice and high service quality

Safe drive monitoring with speed monitors and encoders.

The high system availability is especially crucial in wind turbines for the degree of efficiency and thus for an efficient production of energy. Sensors for safe drive monitoring are used to prevent damage and expensive downtime. The required safety requirements demand an optimal interplay between the safety sensors and the safety monitoring modules. Kübler offers a complete package for this purpose, consisting of certified encoders up to SIL3/PLe and small safety control systems.

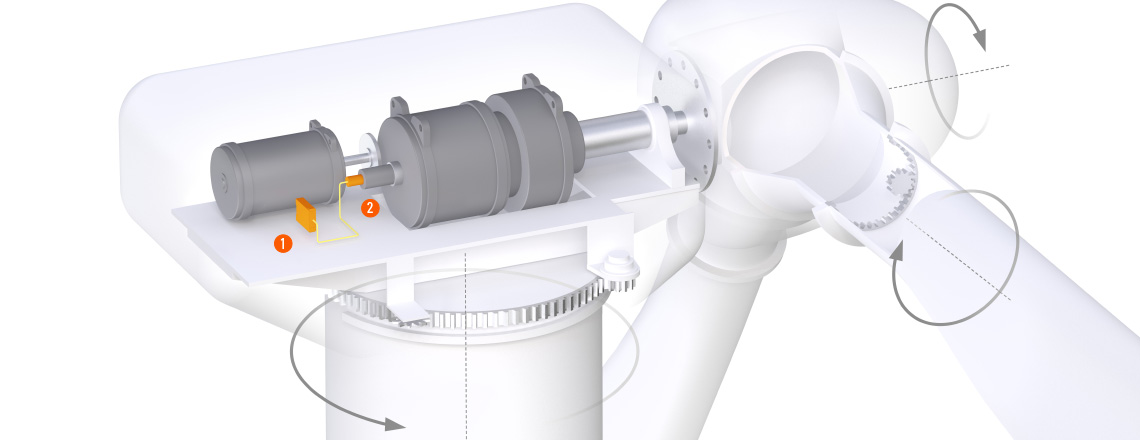

Detection of excessive speeds with a safe overall system

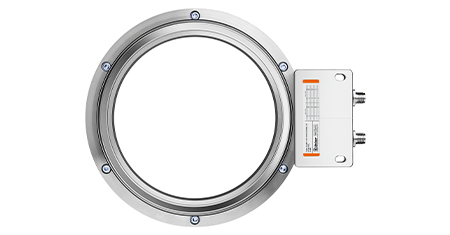

The combination between speed monitor and certified encoders up to SIL3/PLe is the optimal solution for safe drive monitoring and thus for the early detection of excessive speeds. The encoder with SinCos signals, integrated in the slip ring, stands for a reliable speed detection of the rotor shaft.

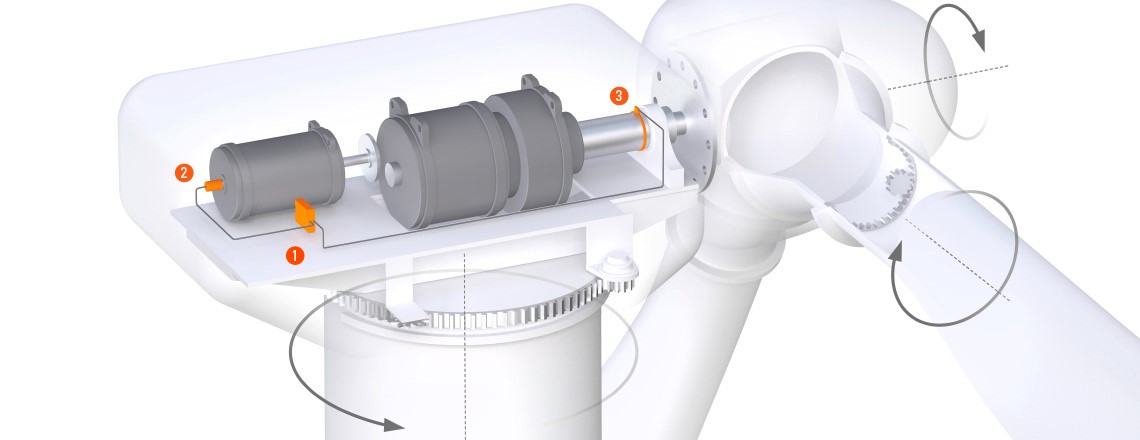

Detection of excessive speeds with two incremental encoders

Alternatively, it is possible to install two encoders at different measurement points in the drive train to ensure a safe drive monitoring. In addition to the speed monitoring, the difference between the rotor and generator shaft is also optimally monitored for slip or gear break.

Your application is our priority

We are happy to take on custom challenges. Describe your application to us. Together we will find the right solution. We look forward to your inquiry.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.