Encoders Absolute multiturn

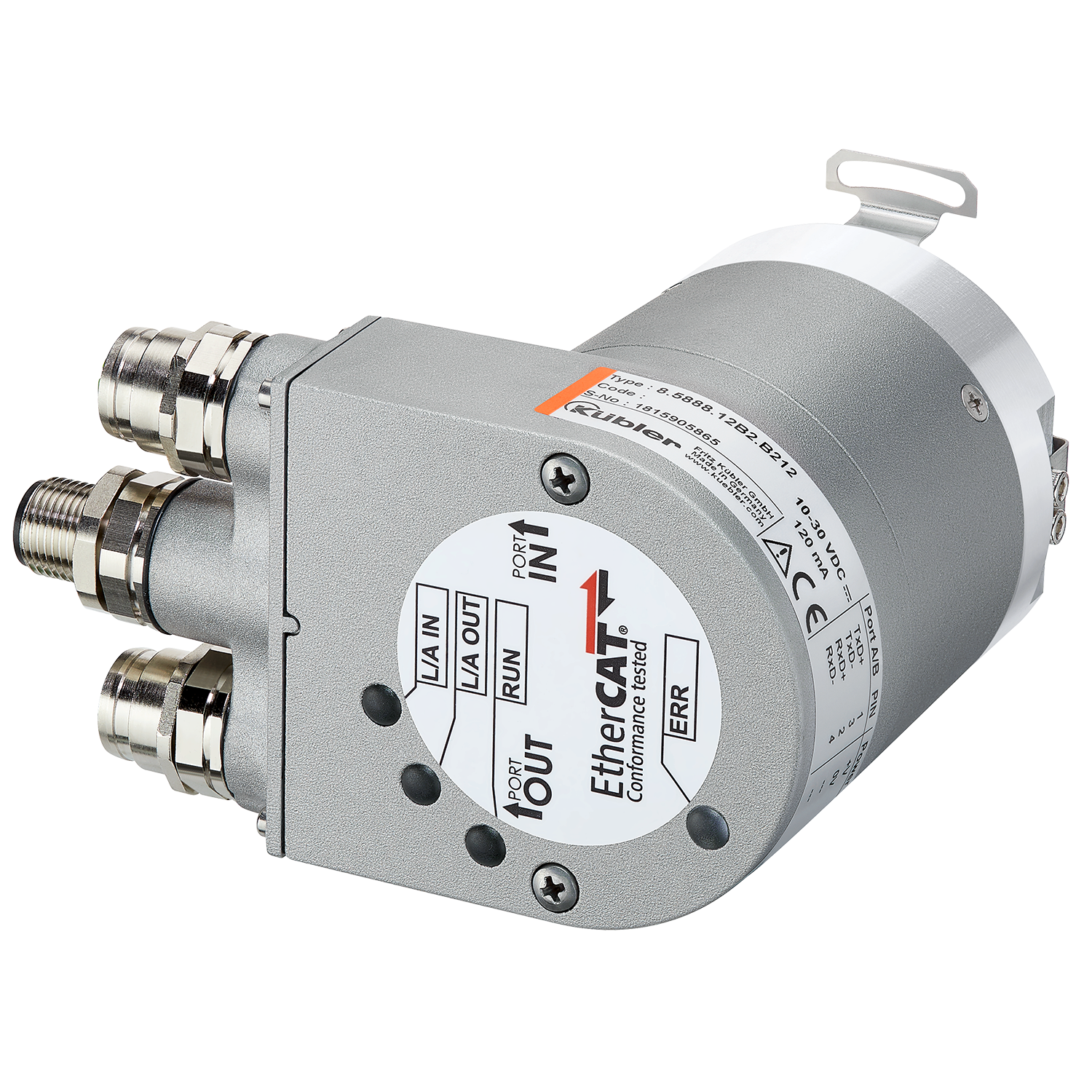

Sendix 5888

|

|

For real-time communication: Industrial Ethernet encoders with EtherCAT interface.

The absolute encoders Multiturn Sendix 5868 / 5888 with 2nd-generation EtherCAT interface and optical sensors can be used in all applications with EtherCAT technology. The data communication is based on CAN over EtherNet and is ideally suited for real-time applications. These encoders are available with shafts up to a maximum diameter of 10 mm or as blind hollow shafts up to 15 mm.

Connectivity stands for the ability to communicate additional information and / or to be integrated in a network. This can take the form of additional interfaces such as OPC-UA (e.g. for additional edge communication) or Industrial Ethernet communication as well as a digital interface such as "BISS" or "SCS open link".

Identification is the ability to transmit technical information by means of an electronic data sheet / type plate. In addition, further information about the machine can be transmitted (e.g. information about the axis where the encoder is installed). Essentially, all the information required in the application for asset management is recorded here.

| Mechanical | |

|---|---|

| Dimension | Ø 58 mm |

| Shaft type |

3/8 " hollow shaft, blind hole 10 mm hollow shaft, blind hole 12 mm hollow shaft, blind hole 14 mm hollow shaft, blind hole 15 mm hollow shaft, blind hole 1/2 " hollow shaft, blind hole |

| Flange type |

Ø 58.00 mm Ø 63.00 mm Ø 65.00 mm Ø 72.00 mm |

| Working temperature | -40 °C ... +80 °C |

| Protection level |

IP65 IP67 |

| Connection types |

M12 connector radial |

| Max. rotational speed |

9.000 min-1 |

| Weight | 570 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. |

16 bits singleturn 12 bits multiturn |

| Power supply |

10...30 V DC |

| Interfaces |

EtherCAT |

- EtherCAT conformance tested.

- Integration of the latest slave – EtherCAT stack from Beckhoff, Version 5.01.

- Ideally suited for use in harsh outdoor environments, thanks to IP67 protection and rugged housing construction.

- Use of CoE (CAN over EtherNet).

- Genuine new position information as a result of minimal cycle time of 62.5 μs in the DC mode.

- Faster, easier error-free connection thanks to M12 connectors.

- Supports Hot Connect.

Accessories

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.1602.0000 |

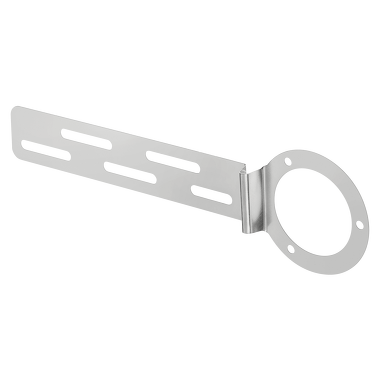

Torque stop, flexible

For hollow shaft encoders

with flange ø 58 mm

Mounting radius 39.5 ... 142.75 mm

Designed for functional safety technology.

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 M3x6 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.4047.00FS |

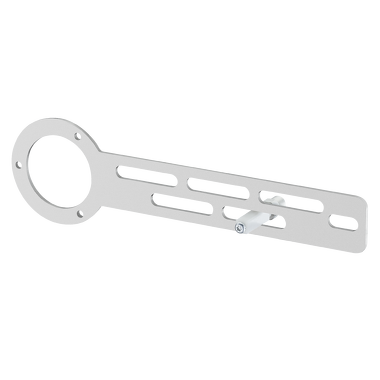

Fastening arm set, rigid

For hollow shaft encoderswith flange ø 58 mm

Mounting radius 32.5 ... 143.5 mm

Designed for functional safety technology.

For applications with very low axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws M3x6 for mounting to the encoder

Connection to the application (not included in delivery)

- 1 torque pin 8.0010.4049.0075

| 8.0010.4051.00FS |

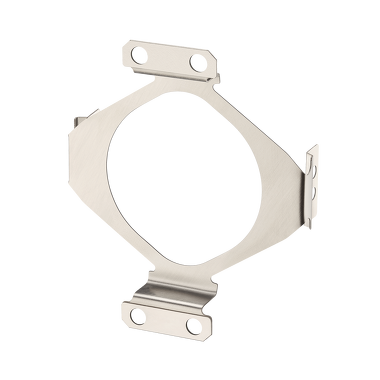

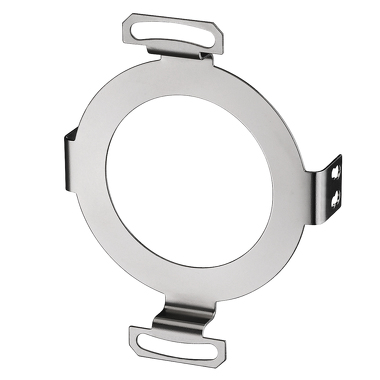

Stator coupling (FS)

For hollow shaft encoders

with flange ø 58 mm

Mounting radius 31.5 mm

Designed for functional safety technology by 4-screw principle.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws M3x6 for mounting to the encoder

Connection to application (not included in delivery)

- 4 screws

| 8.0010.40B2.00FS |

Fastening arm, medium (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.5 ... 45.75 mm

For applications with axial and radial play with constant rotary movements.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40E0.0000 |

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.40L0.0000 |

Fastening arm, short (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.25 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40M0.0000 |

Spring tether element

For hollow shaft encoderswith flange ø 50 ... 58 mm

For applications with low radial and axial play and low dynamics.

Scope of delivery

- Wire spring element

- 1 screw for mounting on the encoder.

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.40W0.0000 |

Stator coupling, double-winged

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 31.5 mm

For lateral mounting on the encoder flange. For applications with high accuracy requirements.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 2 screws

| 8.0010.4D00.0000 |

Spring element, short

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 16 ... 27 mm

For applications with limited axial play at low dynamics and limited installation space.

Scope of delivery

- Spring element (plastic)

- 1 screw for mounting on the encoder

Connection to the application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4H00.0000 |

Spring element, long

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 30.7 ... 36.7 mm

For applications with high axial play, at low dynamics.

Scope of delivery

- Spring element (plastic)

- 1 screw for mounting on the encoder

Connection to the application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4I00.0000 |

Fastening arm, long, (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 36.5 ... 85 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 1 screw

| 8.0010.4R00.0000 |

Cables and connectors

M12 Connector with cable , mit Edelstahl Überwurf

Preassembled cable set

1 x 4 x AWG22 mm2

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.