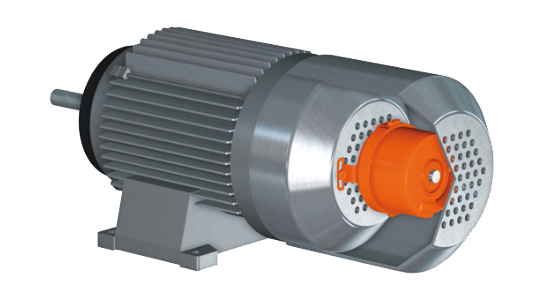

Encoders for asynchronous motors

Optimal speed feedback and position detection with Kübler encoders.

Asynchronous motors are the most used electric drives worldwide in the industrial environment. There are various requirements for the sensors, depending on the application. Kübler has been delivering suitable encoder solutions to renowned manufacturers in this industry for decades. Our customers appreciate the premium quality, robustness and the tried-and-true and sustainable technologies of our products. Together, we will also develop the motors of tomorrow. For example, we have integrated smart bearingless encoders 100% into asynchronous motors. When are your asynchronous motors equipped with Kübler encoders?

Reliable sensor solutions

- Incremental and absolute rotary encoders

- Bearingless encoders – compact solution

- Flexible mechanical mounting and installation solutions

- Individual solutions up to 100% integration

- Numerous electrical interfaces

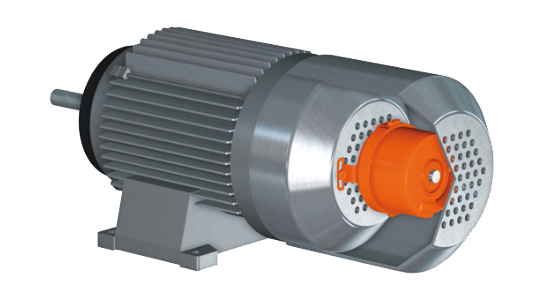

Encoders for asynchronous motors

Optimal speed feedback and position detection with Kübler encoders.

Asynchronous motors are the most used electric drives worldwide in the industrial environment. There are various requirements for the sensors, depending on the application. Kübler has been delivering suitable encoder solutions to renowned manufacturers in this industry for decades. Our customers appreciate the premium quality, robustness and the tried-and-true and sustainable technologies of our products. Together, we will also develop the motors of tomorrow. For example, we have integrated smart bearingless encoders 100% into asynchronous motors. When are your asynchronous motors equipped with Kübler encoders?

Incremental encoders

The incremental Kübler encoders are particularly suitable for speed measuring and thus for an optimal speed feedback. Numerous ordering options, such as shaft and hollow shaft variants as well as mechanical and electrical interfaces, are available to you. Kübler premium quality stands for a flawless continuous operation of your asynchronous motors.

Absolute rotary encoder

Absolute rotary encoders from Kübler in singleturn and multiturn designs are ideal for precisely detecting the angular position of the rotor and thus for position monitoring. Numerous ordering options, such as shaft and hollow shaft variants as well as mechanical and electrical interfaces (SSI, BiSS, CANopen, SinCos, RS422), are available to you.

Absolute rotary encoder without mechanical gears

The heart of these absolute Sendix encoders is the multiple award-winning and patented intelligent Scan Technology™. The optical encoder has all singleturn and multiturn functions on one OptoASIC, thereby allowing for a very high level of reliability with a simultaneously high resolution. The multiturn design achieves up to 41 bits total resolution. An excellent feature is a wear-free functionality due to the optical sensors without mechanical gears.

VIDEOS

DOWNLOADS

20.10.2022

∼ 5.23 MB

Solutions for Drive Technology

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.