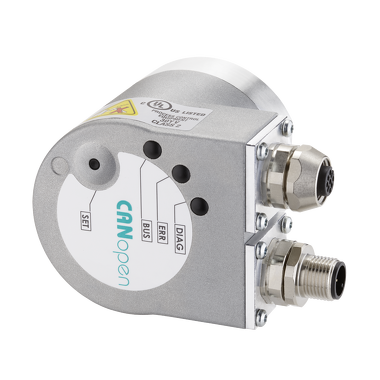

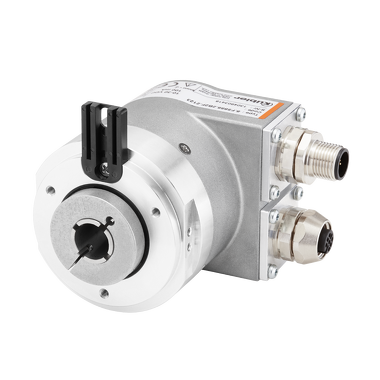

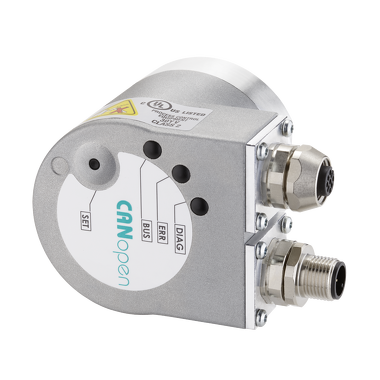

Encoders Absolute multiturn

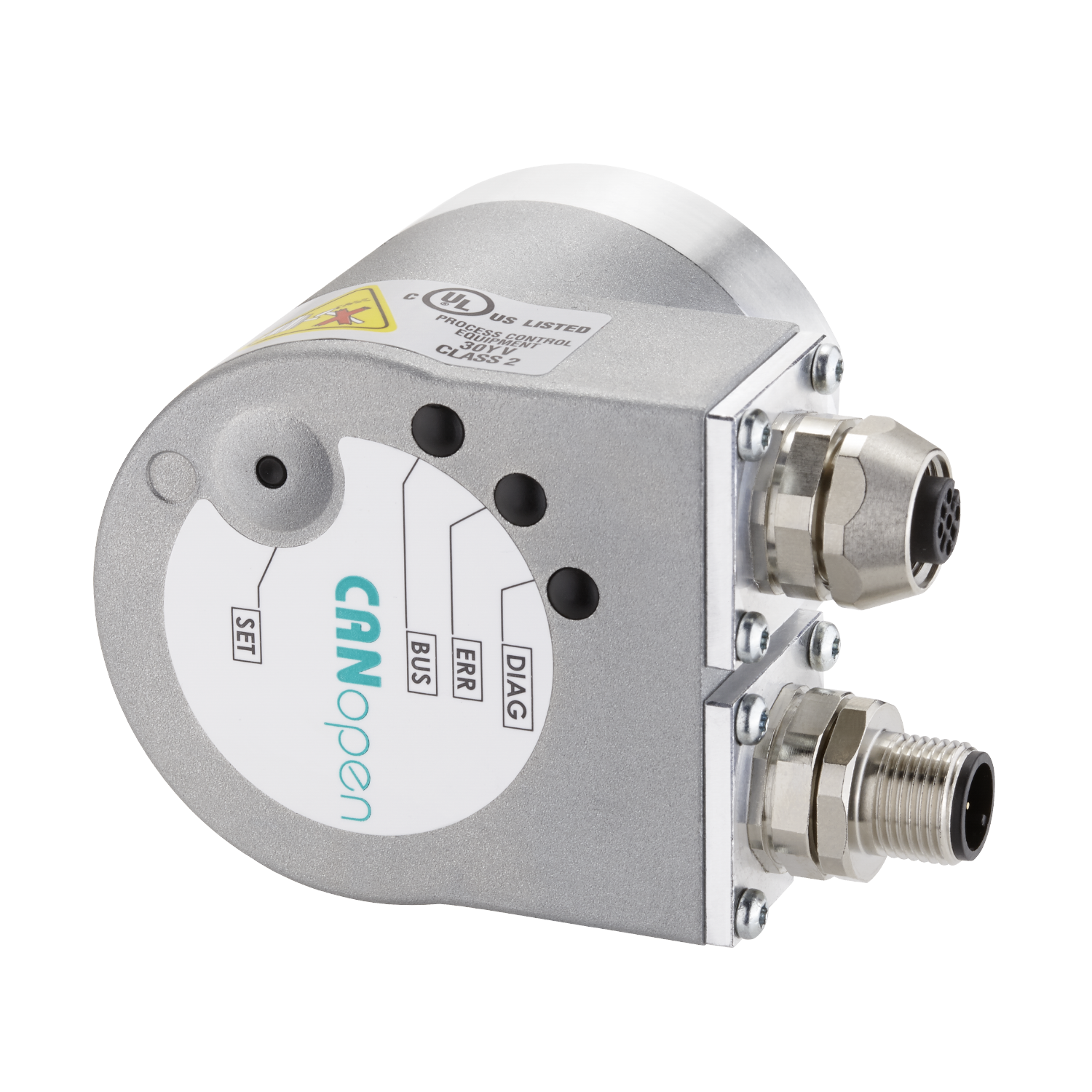

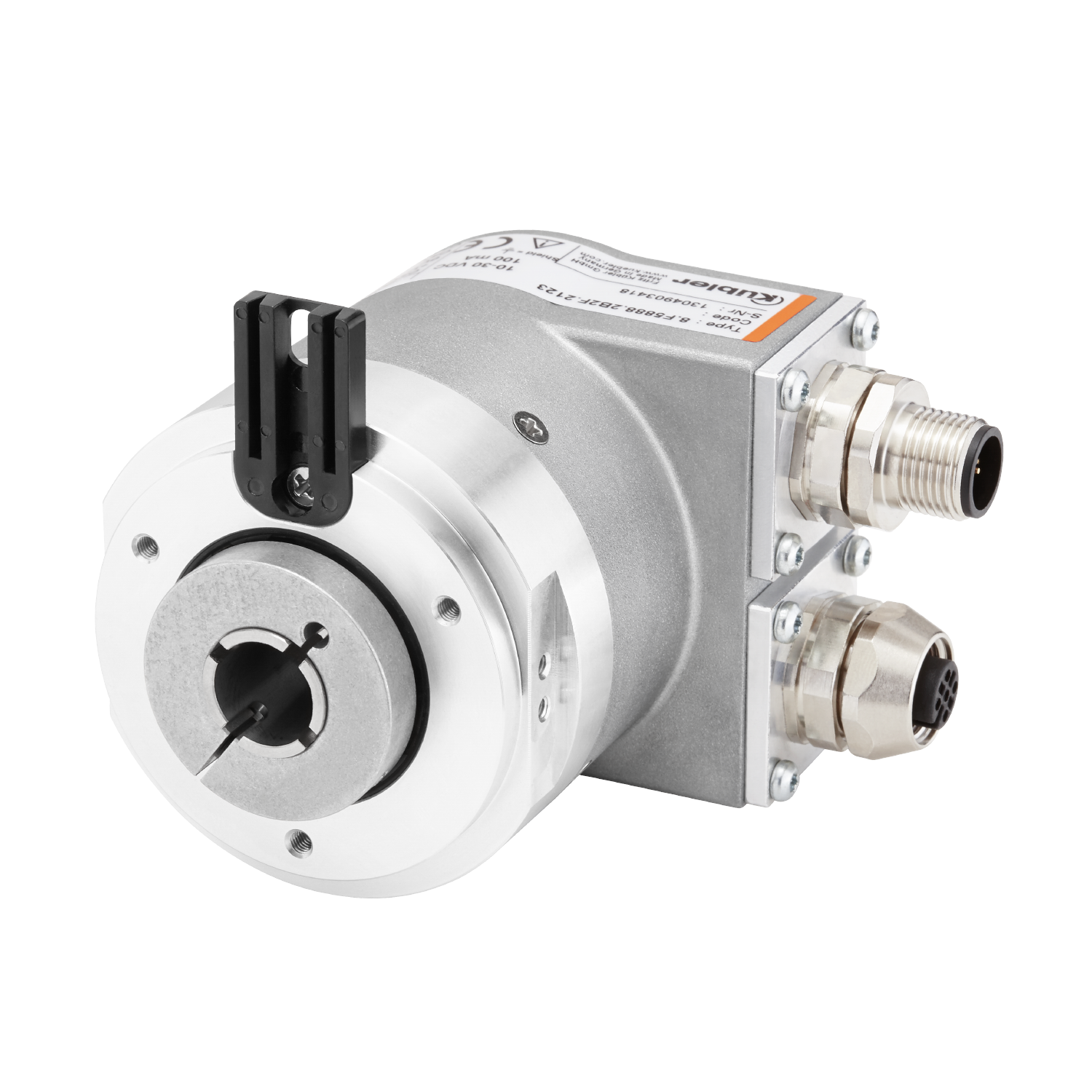

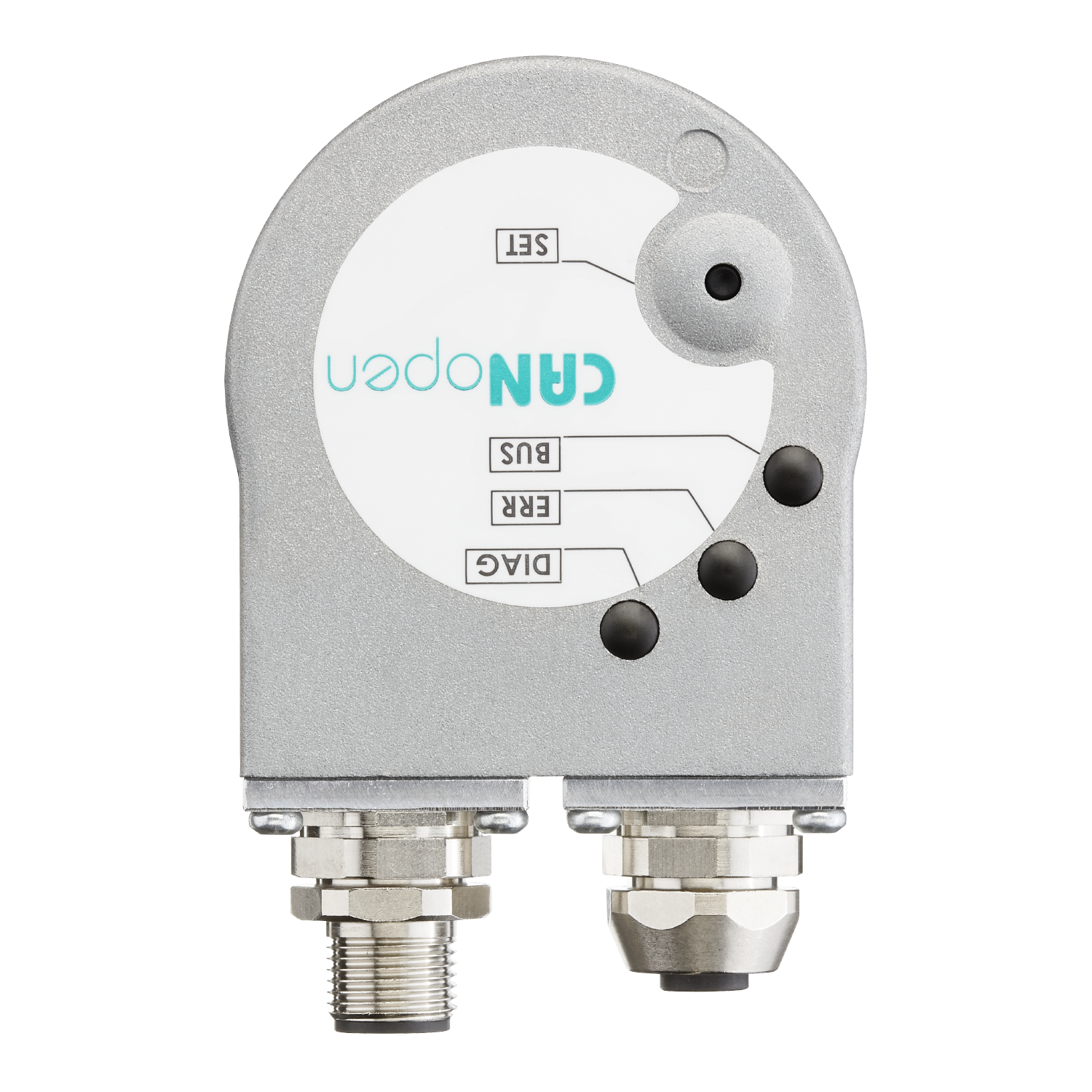

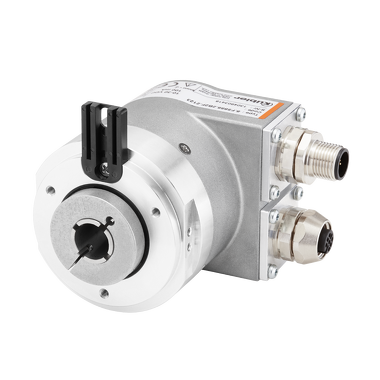

Sendix F5888

|

|

Intelligent Scan Technology™ – electronic field bus encoders.

The Sendix F58 multiturn with patented Intelligent Scan Technology ™ is a particularly high resolution optical multiturn encoder without gears and with 100 percent magnetic insensitivity. 32 bits total resolution, through hollow shaft up to 15 mm and CANopen functionalities according to up-to-date encoder profile.

| Mechanical | |

|---|---|

| Dimension | Ø 58 mm |

| Shaft type |

12 mm hollow shaft, blind hole 10 mm hollow shaft, through 12 mm hollow shaft, through 14 mm hollow shaft, through 15 mm hollow shaft, through |

| Flange type |

Ø 58.00 mm Ø 63.00 mm Ø 65.00 mm Ø 73.40 mm |

| Working temperature | -40 °C ... +80 °C |

| Protection level |

IP65 IP67 |

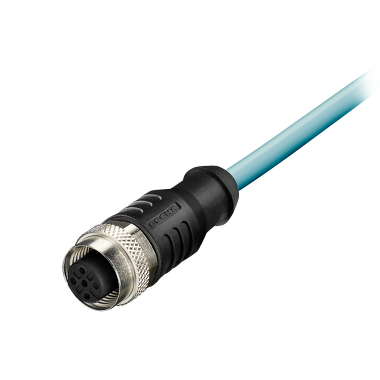

| Connection types |

Tangential cable M12 connector radial |

| Max. rotational speed |

9.000 min-1 |

| Weight | 450 g |

| Electrical | |

|---|---|

| Scanning | optical |

| Resolution max. |

16 bits singleturn 16 bits multiturn |

| Power supply |

10...30 V DC |

| Interfaces |

CANopen |

- Sturdy bearing construction in Safety-Lock™ design for resistance against vibration and installation errors.

- Ideal for use outdoors thanks to IP67 protection and wide temperature range from -40°C up to +80°C.

- Patented Intelligent Scan Technology™ with all singleturn and multiturn functions on one single OptoASIC - offering the highest reliability, a high resolution up to 32 bits and 100% magnetic field insensitivity.

- CANopen with current encoder profile.

- LSS services for configuration of the node address and baud rate.

- Variable PDO mapping in the memory.

- Universal scaling function.

- 32 bits total resolution (16 bit MT + 16 bit ST).

Accessories

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.1602.0000 |

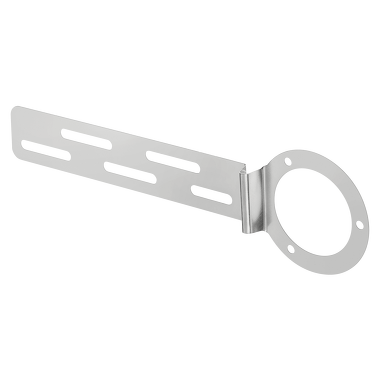

Torque stop, flexible

For hollow shaft encoderswith flange ø 58 mm

Mounting radius 39.5 ... 142.75 mm

Designed for functional safety technology.

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 M3x6 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.4047.00FS |

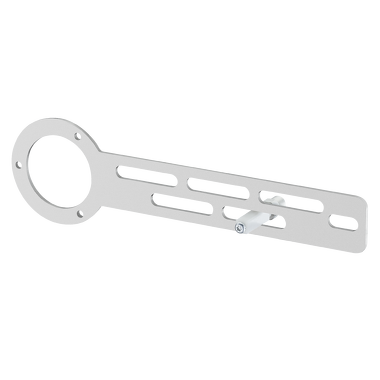

Fastening arm set, rigid

For hollow shaft encoderswith flange ø 58 mm

Mounting radius 32.5 ... 143.5 mm

Designed for functional safety technology.

For applications with very low axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 M3x6 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 torque pin 8.0010.4049.0075

| 8.0010.4051.00FS |

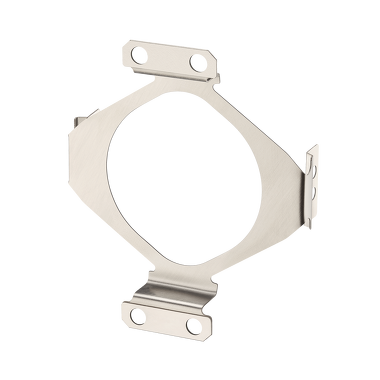

Stator coupling (FS)

For hollow shaft encoders

with flange ø 58 mm

Mounting radius 31.5 mm

Designed for functional safety technology by 4-screw principle.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws M3x6 for mounting to the encoder

Connection to application (not included in delivery)

- 4 screws

| 8.0010.40B2.00FS |

Fastening arm, medium (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.5 ... 45.75 mm

For applications with axial and radial play with constant rotary movements.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40E0.0000 |

Stator coupling

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 32.5 mm

For lateral mounting on the encoder flange.

For applications with axial and radial play at high dynamics.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 3 screws

| 8.0010.40L0.0000 |

Fastening arm, short (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 32.25 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40M0.0000 |

Spring tether element

For hollow shaft encoderswith flange ø 50 ... 58 mm

For applications with low radial and axial play and low dynamics.

Scope of delivery

- Wire spring element

- 1 screw for fastening to the encoder.

Connection to application (not included in delivery)

- 1 screw

| 8.0010.40W0.0000 |

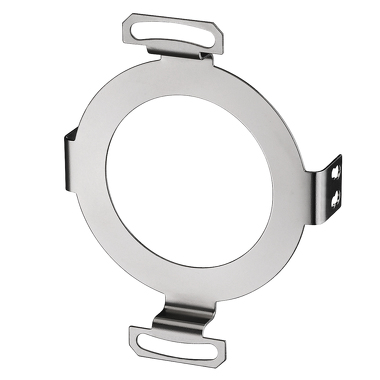

Stator coupling, double-winged

For hollow shaft encoders

with flange ø 50 ... 58 mm

Mounting radius 31.5 mm

For lateral mounting on the encoder flange. For applications with high accuracy requirements.

Scope of delivery

- Stator coupling (stainless steel)

- 4 screws for mounting on the encoder

Connection to the application (not included in delivery)

- 2 screws

| 8.0010.4D00.0000 |

Spring element, short

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 16 ... 27 mm

For applications with limited axial clearance at low dynamics and limited installation space.

Scope of delivery

- Spring element (plastic)

- 1 screw for fastening to the encoder

Connection to application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4H00.0000 |

Spring element, long

For hollow shaft encoderswith flange ø 36 ... 58 mm

Mounting radius 30.7 ... 36.7 mm

For applications with high axial backlash, at low dynamics.

Scope of delivery

- Spring element (plastic)

- 1 screw for fastening to the encoder

Connection to application (not included in delivery)

- Parallel pin 8.0010.4700.0000

| 8.0010.4I00.0000 |

Fastening arm, long, (flexible)

For hollow shaft encoderswith flange ø 50 ... 58 mm

Mounting radius 36.5 ... 85 mm

For applications with axial and radial play at low dynamics.

Scope of delivery

- Torque support (stainless steel)

- 3 screws for fastening to the encoder

Connection to application (not included in delivery)

- 1 screw

| 8.0010.4R00.0000 |

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.

Due to a technical problem, our website is only available to a limited extent. This also affects our download service area. We are already working on the solution and ask for your understanding.